Challenge

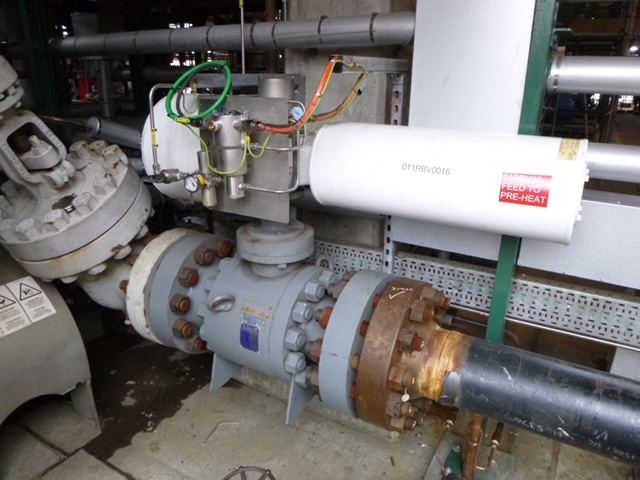

Alongside our strategic energy partner IMI/Maxseal, we were asked to develop a partial stroke test (PST) system that fitted on existing crucial, yet problematic, ESD valves. The aim: to allow site operations to test locally, safely and efficiently without needing any additional equipment or training, and without triggering a valve to close unnecessarily and shut down the plant.