When it comes to choosing the right valve supplier to work with, Engineering, Procurement and

Construction (EPC) contractors, along with end-users, have a lot of options. It’s a crowded market out

there.

Of course, it goes without saying EPCs want to procure the best valve solutions for their customers at the

best possible price – and all without compromising the often complex requirements and specifications of the

order they’re responsible for delivering. And even though valves are regarded as a commodity item, there

can be a lot of risk associated with what are often highly engineered and critical pieces of equipment.

It’s in this context that inexperience, over-simplification, and poorly thought-through processes can result in

expensive errors and costly delays.

Case Study

Ineos: Simplifying complexity, delivering comprehensively

Key Facts

- Onshore gas compression project in the North East of England

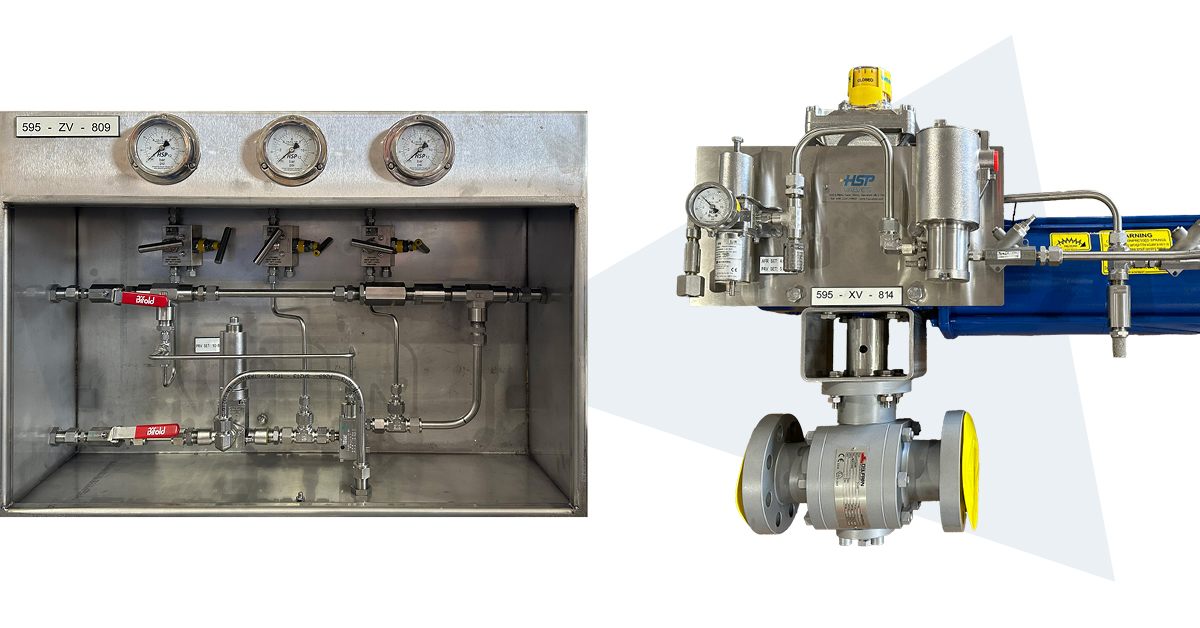

- Large mixed-package of manual, actuated, isolation, and control valves

- Included XV and ESDV valves

- Design, procure, build, and test

- Partial stroke testing of ESDVs

- Increased longevity and reliability of controls through housing inside 316SS cabinets

- Design, build, and test of pneumatic changeover cabinets for continued operation if the compressor fails

The Challenge

We were invited by an EPC to tender for a large mixed-package of high-quality manual, actuated, isolation, and control valves, along with complex control cabinets, for their customer: a large, diversified blue-chip petrochemical company. Out of the 15 items required for the project in the Northeast of England, worth in excess of £1 million, 12 would require designing and building, and the other three control valves procuring from the wider market.

The Solution

As we always do when working with EPCs, we make it our business to get to grips with the technical challenges. That means rigorously defining the complex requirements specification, understanding the project risks, and ensuring we have complete clarity of the end-user’s deliverables. It was this approach and our ability to demonstrate our technical expertise that, according to the EPC, gave them the confidence to award HSP the business.

Once appointed, our Aberdeen-based in-house design team set about designing, procuring, building, and testing the 12 bespoke valves required for the project, including partial stroke testing of ESDVs. We also project-managed the whole process. At the same time, our procurement team’s whole-market approach sourced the three other globe control valves, acting as both initial triage and a second pair of eyes to ensure each valve met the end customer’s needs.

For HSP, design and build, project management, document control, and witness inspection are all part of our value-added approach. For our clients, it means a simplified process, from one valve supplier, that brings fewer risks, fewer delays, and, ultimately, more peace of mind.